KGW Isotherm Dewar Flasks with Flat Bottom, Structure Aluminium Cover

- Special manufactured products are excluded from being returned

Area of Application

- laboratory technique

- medicinal technique

- Biotechnology

- for liquid or solid medias and solid matters (LN2 oder CO2)

- Pressure-less space for coolants

Features of performance

- reliably and economically

- Dewar flasks according to DIN EN ISO 16496

- glass material according to ISO 3585

- nominal capacity from 150ml to 2,1 litres

- protective casing made of stucco aluminium

Description of complete flasks

Types and accessories

- CAL = protective casing out of stucco aluminium

Material

- borosilicate glass 3 ISO 3585

Chemical characteristics

- hydrolytic resistance: according to ISO 719 (98°C)

- hydrolytic resistance: according to ISO 720 (121°C)

- acid resistance: according to ISO 1776

- alkaline resistance: according to ISO 695-A2

Temperature ranges

- glass refill from -200°C to + 150°C, for a short time 200°C

- casing with mounting rubber and Latizell buffer from -10°C to + 60°C

Pressure range

- pressure - less

Technical data

-

ManufacturerKGW-ISOTHERM

-

Country of OriginGermany

-

Capacity (ml)150, 250, 450, 650, 850, 1200, 2100

-

TypeFB 0 CAL, FB 1 CAL, FB 3 CAL, FB 6 CAL, FB 9 CAL, FB 12 CAL, FB 18 CAL

Dewar flasks made of glass

All Dewar flasks manufactured by KGW-ISOTHERM are made of borosilicate glass 3.3 DIN / ISO 3585 made by DWK or Schott Tubing. They are manufactured in compliance with the "Pressure Equipment Directive", Directive 97/23 EC, (N4 with Annex 1) and DIN EN ISO 16496 "Vacuum Insulation Equipment".

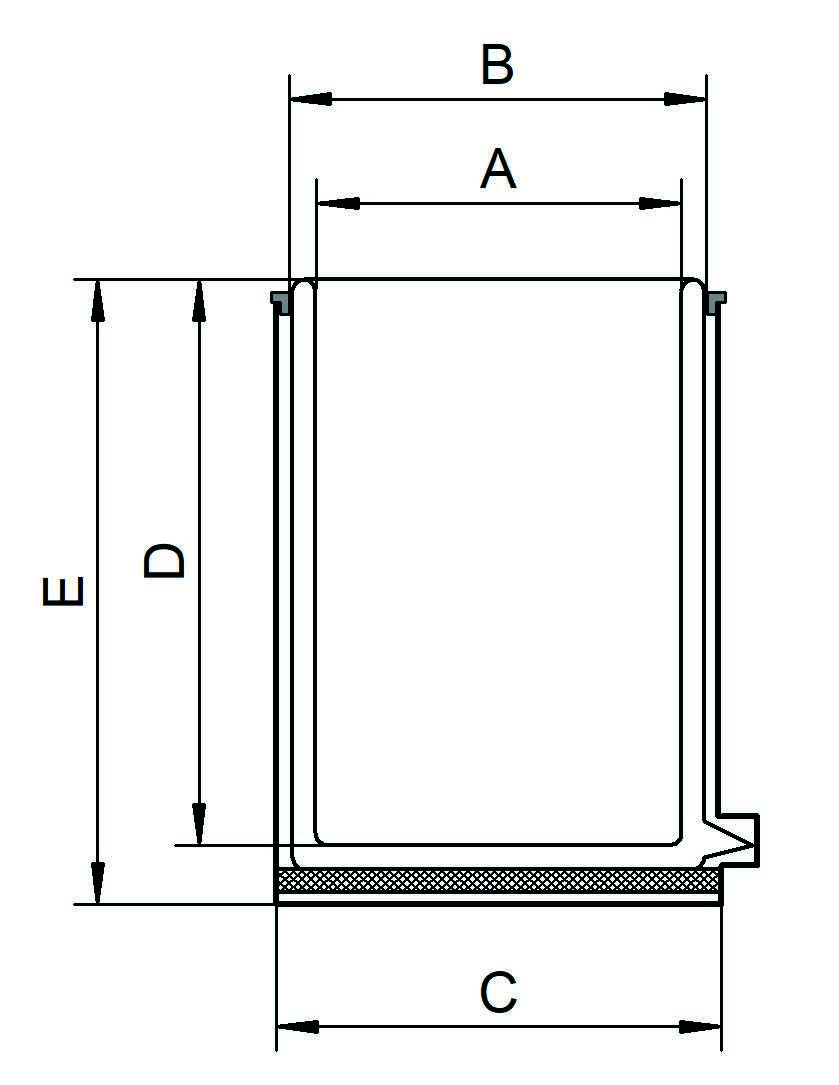

Structure and function of a Dewar flask out of glass

Dewar flasks made of glass are double-walled vacuum-insulated containers. They are used to thermally insulate a stored product (LN2, CO2 or other coolant) from the ambient temperature. Dewar flasks consist of an inner and an outer bulb, which are fused together at the top of the neck opening. The space between the inner and outer pistons is vacuum insulated to prevent thermal contact between the products stored in the Dewar with the ambient temperature (contact heat). In addition, Dewar flasks made of glass are equipped with a silver coating in the vacuum space in order to minimize heat radiation. Best insulation can be achieved by reducing both contact heat (vacuum) and radiation heat (silvering).

For security and work safety reasons, Dewar flasks made of glass always have to be installed in a protective enclosure. This protective cover can be made of sheet metal, aluminum, stainless steel or a transparent PU coating.

All standard glass Dewar flasks only may be used up to a maximum overpressure of 0.1 bar. Higher working pressures on request.

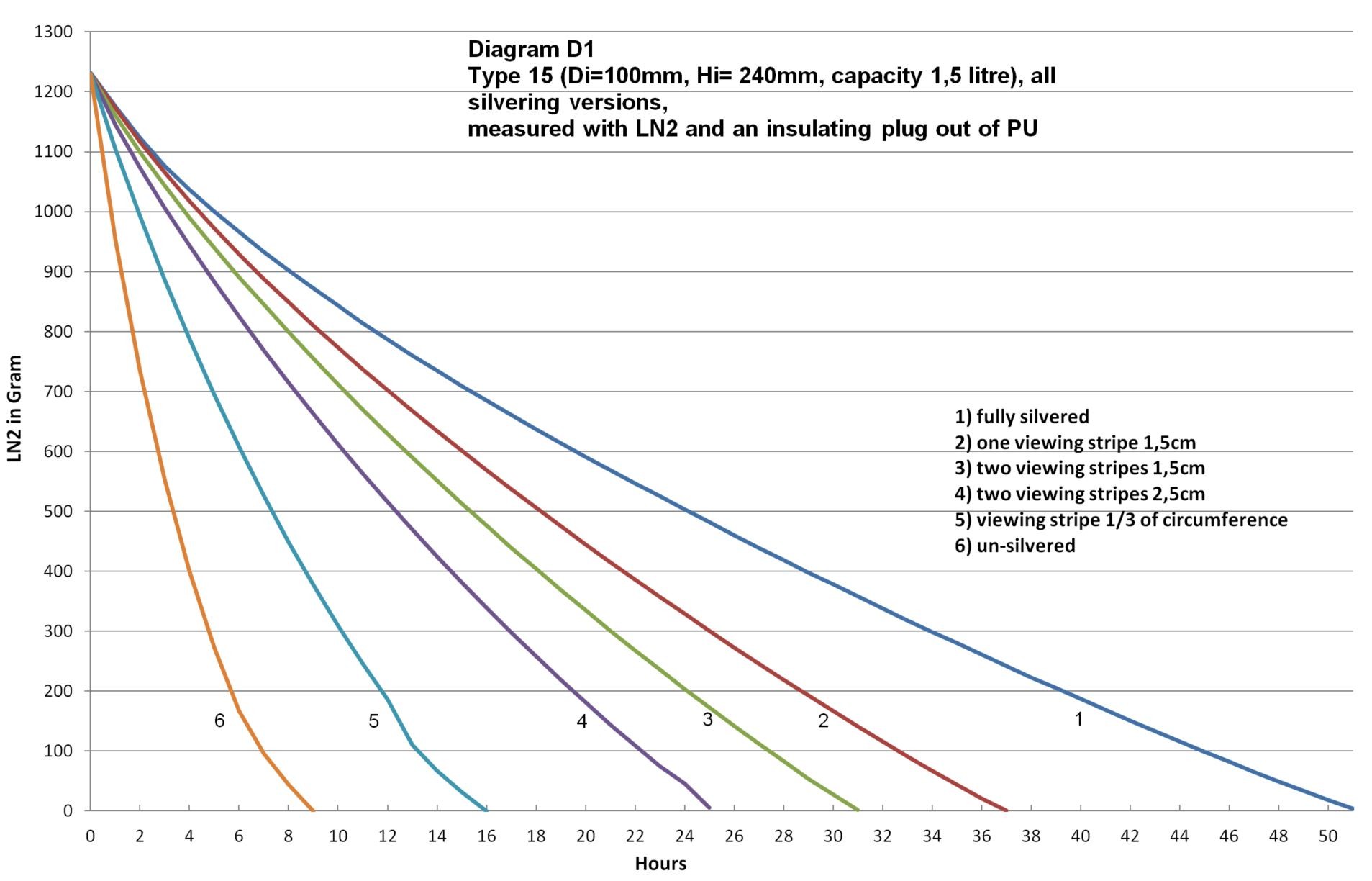

Complete or partly silvered plating’s and their influence on the evaporation rates

Regarding silvered glass Dewar flasks, a distinction has to be made between full silver plating (standard), silver plating with viewing stripes and unsilvered - transparent (customized special design). The lowest radiation losses (heat radiation) are obtained when having the full silver plating. Thus also the lowest evaporation rate / best static holding time of the stored refrigerant are reached with full silver plating. By attaching a viewing stripe in the silver layer, you change the reflection of the radiant heat and therefor also the insulation performance. The bigger a viewing stripe is or the more viewing stripes are incorporated in a silver plating, the greater is the loss of energy of the refrigerant stored in the Dewar vessel. The diagram shows the evaporation rates of liquid nitrogen in a Dewar flask type 15 C, 1.5 liter capacity with different kind of silver layings.