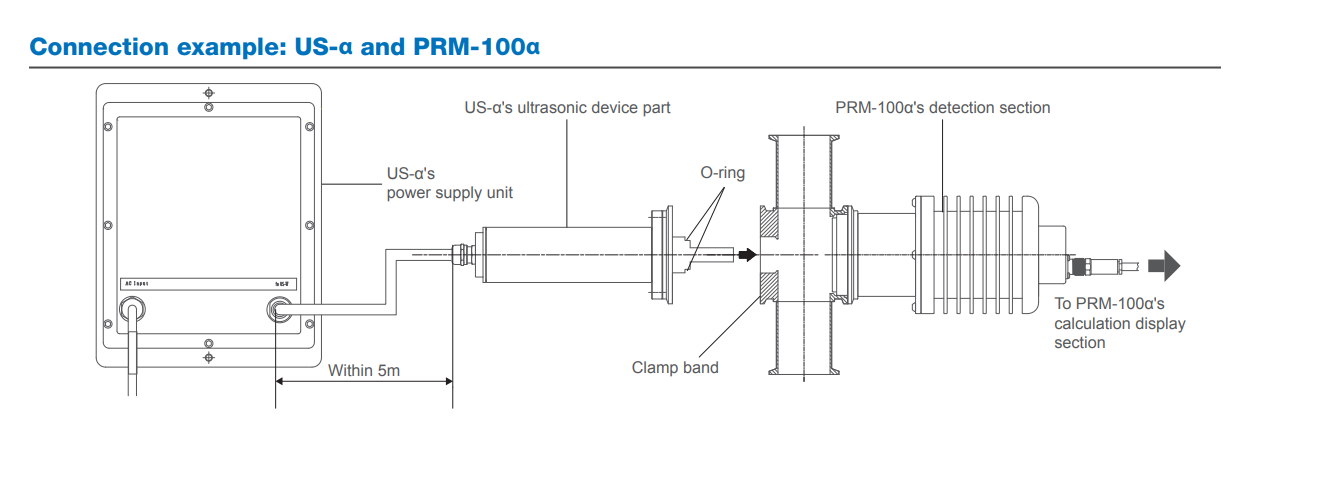

The US-α prevents debris from adhering to the prism surface of the PRM-100α, PRM-2000α and CM-800α. As with other fittings, it can be affixed in the piping system

- For 1S piping

Technical Specifications

| Model | US-α (1S) |

|---|---|

| Cat.No. | 9113-00 |

| Cable | Between ultrasonic cleaner and US-α power supply unit (5m) |

| Power Supply | AC100V~240V, 50/60Hz |

| Dimensions & Weight | ・ultrasonic device part 6.6×7.9×6.6cm,14kg ・power supply part 19.2×10×24cm,3.5kg |

| Power consumption | 5VA |