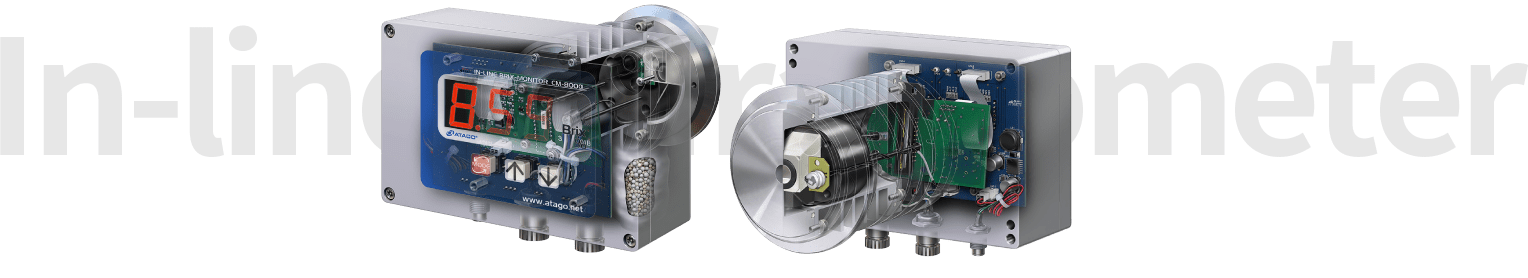

Simple and Easy to Use

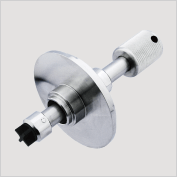

Compact In-line Model

- In-line model can be incorporated into the piping of manufacturing plants, liquid mixing devices, and washing apparatuses for continuous liquid concentration measurement

- Automatic temperature compensation (ATC) for immediate, accurate calibration readings, regardless of sample temperature

- In-line, compact monitor for continuous Brix (0.0 to 78.0%) measurement of sugar content to control mixing, concentration, and fermentation, as well as the concentration of water-based or alkali-based based detergents

9 Reasons to Choose Our Inline Refractometer

|

Wide range with excellent accuracy 0.00 to 80.0% Brix can be measured with a high accuracy of ± 0.1%. Supports various applications with numerous special scales and Intrinsically Safe Explosion-Proof models. Select the most suitable installation method for your application and location! Choose from installtion types such as: pipeline, directly into the tank (ferrule), or hose connector bypass! |

|

Measureable at low and high temperatures.

|

|

|

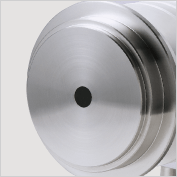

Flat Sample Stage By making the sample stage (wetted part) completely flat, the adhesion of the sample liquid to the prism surface is minimized and is more hygienic. The prism stage is re-polished in 1/100 mm increments during manufacturing to eliminate the chance of slight uneveness that may occur between the prism surface and the prism stage. |

|

Enhanced Cleaning with a Prism Wiper or Ultrasonic Cleaner Due to their nature, some sample liquids will adhere or build up on the prism no matter what after longterm use. For these cases, ATAGO has designed both prism wiper and ultrasonic cleaning devices. Using either of these means is no need to stop the line or remove the in-line refractometer many times just to clean the prism when buildup occurs. |

|

|

Numerous Special Scales Available Special scales are available for many different samples, such as ethylene glycol, propylene glycol, urea, NMP, hydrogen peroxide solution, DMF, saline solution, sodium hydroxide, ethyl alcohol (V / V), ethyl alcohol (W / W), IPA, wheat juice, wine, and more! |

|

Compact All-In-One Unit CM-800α is a model with the operation/display on the front and the detection sensor located on the back. The compact size makes it ideal for installation in various processes and applications. |

|

|

Compatiblity with strong acids and strong alkalis For use with harsh chemicals, the wetted part of the CM-800α series can be customized. It is possible to change the standard stainless steel material to Hastelloy or titanium for added durability. Because all the metal is shaved and polished in-house, we can flexibly respond to changes in materials. |

|

Reliable and high quanity, used in over 80 countries worldwide Customers must stop production if there is an issue with the system or inline refractometer, which can cause a big impact. For that reason, reliability and a good track record are important points. The CM-800α series is a long-selling product that has been highly acclaimed around the world for 20 years. ATAGO provides excellent support and aftercare service from offices and service center around the world should you encounter any issue. |

|

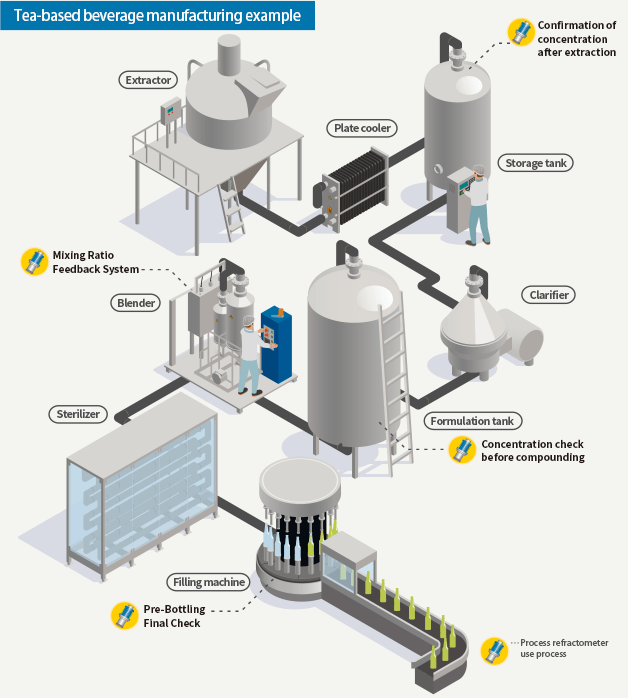

Case Study

|

Block nonconformities by process

Raw material manufacturing process

Check the concentration of the extract Manage extraction yield by measuring the Brix of the extracted solution.Depending on the extraction rate, re-extraction may be performed. Blending process

Mixing Ratio Feedback System The mixing ratio can be detected in real time, and feedback is given so that there are no non-standard products. Filling process

Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifcations.It can also be used to reduce liquid loss by controlling the switching to water during cleaning. |

Technical Specifications

| Model | CM-800α | CM-800α-EG | CM-800α-PG | CM-800α-SW | CM-800α-CaCl₂ | CM-800α-NMP | CM-800α-H₂O₂ | CM-800α-DMF | CM-800α-Urea | CM-800α-Ethanol V/V |

|---|---|---|---|---|---|---|---|---|---|---|

| This new addition to the CM series is compatible with the PRM-100α fittings.Fittings are available in a wide variety of shapes and sizes.The accuracy is ±0.1% across the entire range of 0-80% Brix. | The CM-800α-EG is specially designed for in-line concentration measurements of ethylene glycol solutions used as coolants,LLC,brine,anti-freeze, and de-icing fluids. It also has a secondary scale for the freezing point. | The CM-800α-PG is specially designed for in-line concentration measurements of propylene glycol solutions used as coolants, brine, anti-freeze, and de-icing fluids. It also has a secondary scale for the freezing point. | This is an in-line refractometer for concentrations of sodium chloride in water. | This is an in-line refractometer for concentrations of Calcium chloride in water. | The CM-800α-NMP is specially designed for the measurement of N-methylpyrrolidone solution. | This is an in-line refractometer for concentrations of hydrogen peroxide (H2O2)in water. | This is an in-line refractometer for concentrations of Dimethylformamide concentration in water. |

This is an in-line refractometer for concentrations of Urea (Adblue) in water. Diesel engines in cars, trucks and off-road applications |

This is an in-line refractometer for concentrations of Ethanol (V/V) in water. | |

| Cat.No. | 3564 | 3531 | 3532 | 3533 | 3538 | 3526 | 3522 | 3534 | 3535 | 3523 |

| Scale | Brix [*1] (Automatic Temperature Compensation according to the sample liquid) Temperature |

Ethylene.Glycol (Automatic Temperature Compensation according to the sample liquid) Freezing point Temperature |

Propylene Glycol (Automatic Temperature Compensation according to the sample liquid) Freezing point Temperature |

NaCl(%) (Automatic Temperature Compensation), Temperature | Calcium Chloride(%) (Automatic Temperature Compensation), Temperature |

N-Methyl-2-Pyrrolidone(%) (Automatic Temperature Compensation), Temperature | Hydrogen peroxide(%) (Automatic Temperature Compensation), Temperature |

Dimethylformamide concentration(%) (Automatic Temperature Compensation), Temperature |

Urea(%) (Automatic Temperature Compensation), Temperature | Ethanol(V/V) (%) (Automatic Temperature Compensation), Temperature |

| Measurement Range | Brix : 0.0 to 80.0% Temperature : 5 to 100゚C / 41 to 212゚F |

Ethylene.Glycol. : 0.0 to 90.0% Freezing point : -50 to 0゚C / -58 to 32゚F Temperature : 5 to 100゚C / 41 to 212゚F |

Propylene Glycol. : 0.0 to 90.0% Freezing point : -50 to 0゚C / -58 to 32゚F Temperature : 5 to 100゚C / 41 to 212゚F |

NaCl 0.00 to 28.0% (indication: -2.0 to 28.5%), Temperature -15 to 160˚C (indication: -15 to 160˚C) / 5 to 320°F (indication : 5 to 320°F) |

Calcium chloride 0.0 to 35.0% (indication: -1.0 to 35.5%), Temperature -15 to 160˚C (indication: -15 to 160˚C) / 5 to 320°F (indication : 5 to 320°F) |

N-Methyl-2-Pyrrolidone 0.00 to 100.0% (indication: -2.0 to 100.5%), Temperature -15 to 160°C (indication: -15 to 160°C) / 5 to 320°F (indication : 5 to 320°F) |

Hydrogen peroxide 0.0 to 50.0% (indication: -3.0 to 51.0%), Temperature -15 to 160°C (indication: -15 to 160°C) / 5 to 320°F (indication : 5 to 320°F) |

Dimethylformamide concentration 0.0 to 40.0% (indication: -2.0 to 40.5%), Temperature -15 to 160℃ (indication: -15 to 160℃) / 5 to 320°F (indication : 5 to 320°F) |

Urea 0.0 to 55.0% (indication: -2.0 to 55.5%), Temperature -15 to 160˚C (indication: -15 to 160˚C) / 5 to 320°F (indication : 5 to 320°F) |

Ethanol(V/V) 0.0 to 53.0% (indication: -2.0 to 53.5%), Temperature -15 to 160˚C (indication: -15 to 160˚C) / 5 to 320°F (indication : 5 to 320°F) |

| Resolution | Brix : 0.01 or 0.1% (with an option to display measurements between 0.00 and 9.99% to the 2nd decimal place) Temperature : 1゚C / 1゚F |

Ethylene.Glycol. : 0.1% Freezing point : 1゚C / 1゚F Temperature : 1゚C / 1゚F |

Propylene Glycol. : 0.1% Freezing point : 1゚C / 1゚F Temperature : 1゚C / 1゚F |

NaCl 0.01 or 0.1% (by selection; 0.00 to 9.99%) NaCl 0.1% (10.0 to 28.0%) Temperature 1˚C/1°F |

Calcium chloride 0.1% Temperature 1˚C/1°F |

N-Methyl-2-Pyrrolidone 0.01 or 0.1% (by selection; 0.00 to 9.99%) NMP 0.1% (10.0 to 100.5%) Temperature 1°C/1°F |

Hydrogen peroxide 0.1% Temperature 1°C/1°F |

Dimethylformamide concentration 0.1% Temperature 1℃/1°F |

Urea 0.1% Temperature 1˚C/1°F |

Ethanol(V/V) 0.1% Temperature 1˚C/1°F |

| Measurement Accuracy | Brix : ±0.1% Temperature : ±1゚C / ±1゚F |

Ethylene.Glycol. : ±0.4% Freezing point : ±1゚C / ±1゚F Temperature : ±1゚C / ±1゚F |

Propylene Glycol. : ±0.4% Freezing point : ±1゚C / ±1゚F Temperature : ±1゚C / ±1゚F |

NaCl ±0.1% (based on sucrose solution) Temperature ±1˚C/1°F |

Calcium chloride ±0.2% Temperature ±1˚C/1°F |

NMP ±0.1% (based on sucrose solution) Temperature ±1°C/1°F |

Hydrogen peroxide ±0.6% Temperature ±1°C/1°F |

Dimethylformamide concentration ±0.3% (0.0 to 40.0%) | Urea ±0.3% Temperature ±1˚C/1°F |

Ethanol(V/V) ±1.0% Temperature ±1˚C/1°F |

| Temperature compensation range | 5 to 100゚C (Automatic Temperature Compensation) | 5 to 100゚C (Automatic Temperature Compensation) |

5 to 100゚C (Automatic Temperature Compensation) |

5.0 to 100.0˚C (Automatic Temperature Compensation range) | 10 to 40˚C (Automatic Temperature Compensation range) | 10 to 60°C (Automatic Temperature Compensation range) | 10 to 35°C | 5.0 to 40.0℃ (Automatic Temperature Compensation range) | 10 to 40˚C (Automatic Temperature Compensation) |

5.0 to 100.0˚C (Automatic Temperature Compensation range) |

| Wetted parts temperature resistance | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C | -30 to 150゚C |

| Ambient Temperature | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C | 5 to 40゚C |

| Indication | Brix : -2.0 to 80.5% Temperature : 0 to 130゚C / 32 to 266゚F |

Ethylene.Glycol. : -2.0 to 105.5% Freezing point : -50 to 0゚C / -58 to 32゚F Temperature : 0 to 130゚C / 32 to 266゚F |

Propylene Glycol: -2.0 to 105.5% Freezing point :-50 to 0゚C / -58 to 32゚F Temperature : 0 to 130゚C / 32 to 266゚F |

|||||||

| Light source | LED(D-line approximation) | LED(D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) | LED (D-line approximation) |

| Temperature sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor | Thin film platinum sensor |

| Materials in contact with the solution | Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316 |

Prism : Sapphire Prism stage : SUS316L |

Prism : Sapphire Prism stage : SUS316L |

| Prism pressure resistance | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) | 0.98MPa(10kgf/cm2) |

| Output |

Recorder output: DC 4 to 20mA Any value between Brix 1% through 80% can be set. Temperature -15.5 to 160.5°C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA EG Concentration value can be set in 1% increments.Freezing point temperature range can be set in 10°C or 10°F increments. Temperature -15.5 to 160.5°C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA PG Concentration value can be set in 1% increments. Freezing point temperature range can be set in 10°C or 10°F Temperature -15.5 to 160.5°C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA Any value between NaCl 1% through 28.5% can be set. RS-232C output |

Recorder output : DC 4 to 20mA Temperature -15.5 to 160.5˚C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA Any value between NMP-2.0% through 100.5% can be set. RS-232C output |

Recorder output: DC 4 to 20mA Any value up to Hydrogen peroxide 51.0% can be set. (The difference between the upper and lower limit values Temperature -15.5 to 160.5°C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA Dimethylformamide concentration up to 40.5% can be set in 1% Temperature -15.5 to 160.5℃ = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA Any value up to urea 55.5% can be set. Temperature -15.5 to 160.5°C = 4 to 20mA RS-232C output |

Recorder output: DC 4 to 20mA Any value between Ethanol(V/V) 1% through 53.5% can be set. Temperature 0 to 130˚C = 4 to 20mA RS-232C output |

| Power Supply | 100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

100 to 240V (50/60Hz) (voltage fluctuation not to exceed ±10%) CM-800α : DC24V (Allowable fluctuation is ±10%) AC adapter AD-32, AD-33 or AD-34 (optional): AC 100-240V 50/60Hz |

| International Protection Class | IP67 Dust-tight and Protected against splashing water. | IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

IP67 Dust-tight and Protected against splashing water. |

| Included Accessories | Power input cable (1m) [*2] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] | Power input cable (1m) [*1] |

| Dimensions & Weight | 16.0 x 17.0 x 11.0cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

16 x 17 x 11cm, 2.4kg (Main Unit only) |

| Power consumption | 3VA | 3VA | 3VA | 3VA | 3VA | 3VA | 3VA | 3VA | 3VA | 3VA |

|

Brix measurement determines pure sucrose content in samples and is not only a well-known application in the food and beverage industry, but also in the chemical segment. The degree Brix is represented by the following equation: 1 degree Brix (°Bx) = 1g of sucrose / 100g of solution But does it apply to any kind of sample? Is 12 °Bx in orange juice equal to 12 g of sugar? In practice, not necessarily. The Brix scale is used to measure sugar content in substances such as soft drinks, fruit juices and tomato concentrates, as well as products such as cutting oil, which are very often far away from pure sucrose/water solutions. This has led to some confusion especially when comparing results obtained with different measuring techniques |

Ethylene glycol is an organic compound with the formula (CH₂OH)₂. It is mainly used for two purposes, as a raw material in the manufacture of polyester fibers and for antifreeze formulations. It is an odorless, colorless, flammable, viscous liquid. | Propylene glycol (IUPAC name: propane-1,2-diol), according to the National Library of Medicine and Agency for Toxic Substances and Disease Registry, is a synthetic liquid substance that absorbs water.[4] It is labelled an organic compound in chemistry due to its carbon attributes. Its chemical formula is CH3CH(OH)CH2OH. It is a viscous, colourless liquid, which is nearly odourless but possesses a faintly sweet taste. Containing two alcohol groups, it is classed as a diol. It is miscible with a broad range of solvents, including water, acetone, and chloroform. In general, glycols are non-irritating, have very low volatility and very low toxicity.[5] It is produced on a large scale primarily for the production of polymers. In the European Union, it has the E-number E1520 for food applications. For cosmetics and pharmacology, the number is E490. Propylene glycol is also present in propylene glycol alginate, which is known as E405. Propylene glycol is a compound which is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA) under 21 CFR x184.1666 and is also approved by FDA for certain uses as an indirect food additive. Propylene glycol is approved and used as a vehicle for topical, oral and some intravenous pharmaceutical preparations in U.S. and in Europe. |

Sodium chloride, commonly known as salt, is an ionic compound with the chemical formula NaCl, representing a 1:1 ratio of sodium and chloride ions. With molar masses of 22.99 and 35.45 g/mol respectively, 100 g of NaCl contains 39.34 g Na and 60.66 g Cl | Calcium chloride is an inorganic compound, a salt with the chemical formula CaCl₂. It is a white crystalline solid at room temperature, and it is highly soluble in water. It can be created by neutralising hydrochloric acid with calcium hydroxide | N-Methyl-2-pyrrolidone is an organic compound consisting of a 5-membered lactam. It is a colorless liquid, although impure samples can appear yellow. It is miscible with water and with most common organic solvents. | Hydrogen peroxide is a chemical compound with the formula H₂O₂. In its pure form, it is a very pale blue liquid that is slightly more viscous than water. It is used as an oxidizer, bleaching agent, and antiseptic, usually as a dilute solution in water for consumer use, and in higher concentrations for industrial use. | Dimethylformamide is an organic compound with the formula (CH₃)₂NCH. Commonly abbreviated as DMF, this colourless liquid is miscible with water and the majority of organic liquids. DMF is a common solvent for chemical reactions. |

AdBlue® is an aqueous solution with a concentration of 32.5 % urea. In North America, it is referred to as DEF (for "diesel exhaust fluid"). Urea reacts with nitrogen oxides and creates environmentally safe nitrogen and water. AdBlue® is therefore added to diesel to lower nitrogen oxide emissions. In countries where taxes are graduated according to vehicle emissions, reduced emissions of nitrous oxides may be cost efficient. Moreover, the addition of AdBlue® results in a reduction of fuel consumption by 3 % to 8 %. The international standard ISO 22241 demands the analysis of AdBlue® using one of several defined methods. ISO 22241-2 Annex C specifies the determination of urea content in AdBlue® with refractive index measurement |

Ethanol molecules are smaller than water molecules, so when the two liquids are mixed together the ethanol falls between the spaces left by the water. It's similar to what happens when you mix a liter of sand and a liter of rocks.

|

-

ManufacturerAtago Co Ltd

-

Country of OriginJapan

-

ModelCM-800α, CM-800α-NMP, CM-800α-EG, CM-800α-PG, CM-800α-SW, CM-800α-H2O2, CM-800α-Ethanol V/V, CM-800α-IPA, CM-800α-Urea, CM-800α-Plato, CM-800α-DMF, CM-ISα-Hastelloy, CM-800α-CaCl₂, CM-800α-NaOH, CM-INTANK(A), CM-INTANK(D)

-

RangeBrix : 0.0 to 80.0%, NMP Concentration: 0.0-100.0%, Ethylene Glycol : 0.0 to 90.0%, Propylene Glycol : 0.0 to 90.0%, Urea (Adblue) : 0.0~55.0%, Ethanol(V/V) :0.0~53.0%, Salinity : 0.0 to 28.0%, Dimethylformamide Concentration 0.0 to 40.0%, Hydrogen Peroxide 0.0 to 50.0%, IPA 0.0 to 50.0%, Calcium Chloride 0.0 to 35.0%, Sodium Hydroxide NaOH(W/W):0.0~38.0%, Brix : 0.0 to 33.0%

-

AccuracyBrix : ±0.1%, NMP Concentration: ± 0.1%, Ethylene Glycol ±0.4%, Propylene Glycol ±0.4%, Urea (Adblue) : ±0.3%, Ethanol(V/V) : ±1.0%, Salinity : ±0.1%, Dimethylformamide Concentration ±0.3%, Hydrogen Peroxide ±0.6%, IPA ±0.4%, Calcium Chloride ±0.2%, Sodium Hydroxide NaOH (W/W) : ±0.1%

-

CommunicationsDC 4 to 20mA and RS-232C Output

-

Materials in Contact with the SolutionPrism: Sapphire, Prism stage: SUS316L, Titanium, Hastelloy

-

International Protection ClassIP67 Water Resistant

-

Installation TypeIn-Line

-

ApplicationBrix, Ethylene Glycol, Propylene Glycol, N-Methyl-2-Pyrrolidone, Urea (Adblue) in Water, Ethanol (V/V) in Water, Sodium Chloride in Water (Salinity), Dimethylformamide Concentration in Water, Hydrogen Peroxide(%), Isopropyl Alcohol, Calcium Chloride, Sodium Hydroxide NaOH in Water