Freely and Easily, IoT

Freely and Easily, IoT

Smart Monozukuri Support Tool

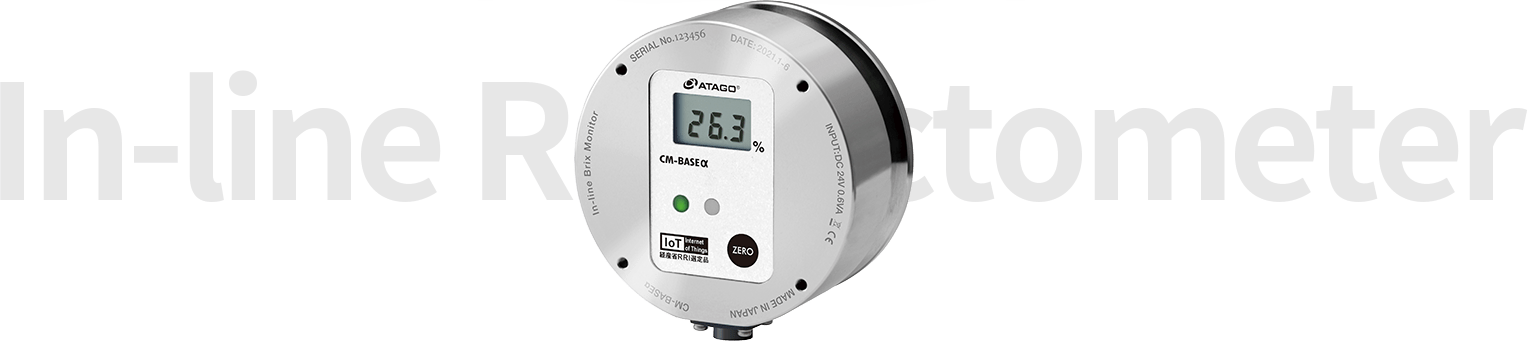

In-line Concentration Monitor

CM-BASEα

8 Reasons to Choose CM-BASEα

-

ManufacturerAtago Co Ltd

-

Country of OriginJapan

-

ModelCM-BASEα(A+D), CM-BASEα-Plus, CM-BASEα-MAX, CM-BASEα-03S, CM-BASEα-38S, CM-BASEα-39S, CM-BASEα-40S, CM-BASEα-Urea

-

RangeBrix : 0.0 to 53.0%, Brix : 0.0 to 93.0%, Salinity : 0.0~28.0%

-

AccuracyBrix : ±0.5%, Brix : ±0.2%, Salinity : ±0.5%

-

CommunicationsDC 4 to 20mA and RS-232C Output

-

Installation TypeIn-Line

-

ApplicationBrix, Ethylene Glycol, Propylene Glycol, N-Methyl-2-Pyrrolidone, Urea (Adblue) in Water, Ethanol (V/V) in Water, Sodium Chloride in Water (Salinity), Dimethylformamide Concentration in Water, Hydrogen Peroxide(%), Isopropyl Alcohol, Calcium Chloride, Sodium Hydroxide NaOH in Water

Applications

BeveragesFruit juice, carbonated beverages, sports drinks, Flavored beverages |

There are many varieties of drinks that come to mind when it comes to "beverages." With the exception of tea and sports drinks, on the hole, beverages contain about 10g of sugar per 100g. Sugar level, as well as concentration (Brix), can be measured with in-line refractometers. In-line meters are used to provide measurements on samples in blending equipment that mix raw materials and water, as well as a pass/fail check for products before filling. |

|

CASE STUDY Blending Mixing Ratio Feedback System In real-time, measure mixing ratio and respond by changing flow volume adjustment. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. For carbonated beverages When adding carbonation before filling, the concentration can be controlled once the carbonation is added. Brix example Sports drinks usually measure about 6% Brix. |

Coffee・Teacoffee milk, Tea |

It is said that Japan is the largest consumer of canned coffee, but the aspect foreigners find most surprising is the high-level quality of its taste. There are an abundance of varieties, and what's more, they preserve that high-quality taste with a flavor that is on par with freshly brewed coffee. Japanese canned coffee manufacturers are in constant pursuit of that delectable flavor, and to maintain that same tastiness, inline refractometers are used at many stages in the process. Currently, all kinds of means are used to strengthen canned coffee's brand image and increase recognition, such as creating and instilling the brand with high-end, elite quality. |

|

CASE STUDY Extraction Concentration measurement prior to mixing Concentration measurement prior to mixing Blending Mixing Ratio Feedback System In real-time, measure mixing ratio and respond by changing flow volume adjustment. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. Brix example Tea drinks (no added sugar) 0.2 to 0.5% Brix. |

Beer

|

Composed of raw ingredients such as malt derived from sprouted barley, hops, brewer's yeast, and water, beer is universally cherished for that distinct aroma of its hops and that cool, refreshing, fizzy feeling produced by its carbonation. Beer is divided into different categories such as top-fermenting ales and bottom-fermenting lagers, depending on the brewing method and the type of yeast. Generally speaking, the flavor of "beer" greatly differs, depending on the brewing method. Perhaps such vast flavor variety is the connection to beer's longstanding appeal. |

|

CASE STUDY Preparation Wort Concentration Control Wort, the source of beer, is measured most commonly during the boiling process. Fermentation Fermentation Process Management During fermentation, yeast converts most of the sugar in the wort to alcohol and carbon dioxide gas. Brix is used to determining when to stop the alcohol fermentation process. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. Brix example Beer measures about 4 to 5% Brix. |

Gelatin &

|

Imagine the sound of quivering gelatin, "wibbly wobbly, jiggly wiggly". Gelatin comes in many forms, from a confectionery made to be an easily ingested food with highly beneficial nutrients, to a stewed, jellied dish as a cuisine. Originally, it is a confectionery made from a combination of fruit juice, gelatin, and sugar. Variations are made by adding other ingredients such as fruit, spices, and acidulants. Jelly beans, gummy candies and the like are foods made from processed gelatin. |

|

CASE STUDY Blending Mixing Ratio Feedback System In real-time, measure mixing ratio and respond by changing flow volume adjustment. Concentrate status check For gummy candy: Concentration is checked when mixing the raw materials, heating up the slurry, and concentrating. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. Brix example Jello is around 15 to 20% Brix while gummies are closer to 80% Brix. |

Soy Milk & Tofu |

Tofu contains many necessary nutrients for us humans, while soy milk is a liquid produced when soybeans are boiled and crushed. The protein in soymilk is said to be nutritious and of high quality. In fact, the beautifying effects of the isoflavones in soybeans are famous. To produce tofu, soybeans are soaked in water for a time and then, while adding more water, the beans are grounded to make a paste (Namago). This paste is then boiled and strained, separating it into soy milk and “okara”, or bean curd. Bittern (a coagulant) is added to the soy milk which turns it into tofu and of course frying creates fried tofu. |

|

CASE STUDY Submerge and Soak・Grind Concentration measurement of Namago Namago (bean paste) can vary in concentration depending on the amount of moisture soybean contains and how much water is absorbed during the soaking process. The concentration is adjusted by adding water depending on its hardness. Point Soy milk can be categorized to nonadjusted, prepared soy milk, and soy milk beverages depending on the amount of soy that remains as solids. This makes the monitoring of the soy concentration to be one of the important factors to manage. Blending Mixing Ratio Feedback System In real-time, measure mixing ratio and respond by changing flow volume adjustment. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. |

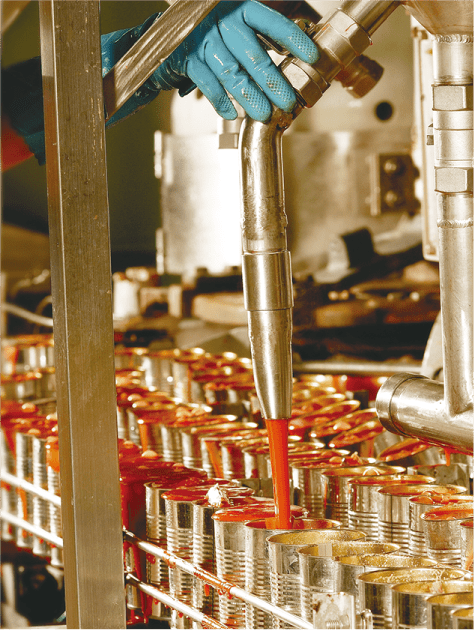

Tomato Puree |

Tomatoes are a vegetable with such great nutritional value that it can almost be said that, "even malnourished people become robust and their strength improves when it's tomato ripening season." This physically revitalizing appeal which is recognized all over the world, is certainly attributed to their high nutritional value. Moreover, people may find tomatoes' exquisite balance of sweetness and sourness to be simply irresistible to their taste buds. Tomato purée is a concentrate made by crushing tomatoes and straining them through a sieve.It is also used as a raw ingredient for ketchup. |

|

CASE STUDY Straining Concentration measurement of pre-blending solution Check that the tomato juice concentration (Brix) made from raw materials is within specifications. Concentration Concentrate status check Used to check the concentration. Brix example For tomato purees, unsalted soluble solids must be no less than 8% but under 24%. When it is further concentrated, and soluble solids become greater than 24%, it is called tomato paste. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. |

BrineEssential for fisheries, pasta, instant ramen noodles and more! |

An overabundant intake of salt is linked to a risk of lifestyle diseases such as high blood pressure and heart disease. From a different aspect, salt plays an important part in our bodies. Salt has a role in adjusting the amount of moisture of our bodies; chlorine, which is composed of salt, is the primary component of stomach acid and supports digestion, and within saliva, salt enlivens the function of digestive fluids. Such is the vital role salt plays as a necessity for life. However, still more, in terms of taste perception, insufficient salt leads to bland dishes that fall short on flavor. Salt is a crucial element in expertly drawing out the flavor of ingredients. |

|

CASE STUDY Boiling in a pot with high-temperature brine Concentration control of boiled cooking water Shirasu (small white sardines) must be treated immediately as it does not remain fresh for long. The boiling water to cook shirasu is kept at 80°C in a hot pot with salinity at about 3.5%. During the boiling process, the salt is added to compensate for the loss caused by evaporation and salt that gets absorbed in shirasu. For Cup Ramen Even in the manufacturing process of cup ramen, the concentration of saline solution mixed in the noodles is controlled by an in-line refractometer that is directly attached to the tank. |

Vinegar |

Vinegar is said to be quite good for the body. There are many kinds of vinegar such as grain vinegar made from rice, wheat, corn, and the like, and fruit vinegar made from fruits. Although vinegar is a type of liquid seasoning, it has countless beneficial effects including constipation relief, high blood pressure prevention, appetite stimulation, fatigue alleviation, and anti-microbial effects. Recently, there has been an increase in products that are easier to adopt into our lifestyle, such as drinking vinegars (shrubs). |

|

CASE STUDY Acetic acid fermentation Fermentation Process Management The progress and condition of acetic acid fermentation can be checked. About vinegar The Japanese Agricultural Standard (JAS), "Consumable Vinegar Japan Agricultural Standards" defines vinegar to be made by brewing grains or fruits and then adding acetobacter to facilitate fermentation. Bottling Pre-Bottling Final Check A final check on the product before bottling is made to make sure it is within specifications. Controlling the switch between various liquids can help reduce liquid loss. |

Wastewater / Effluent Water |

It goes without saying that manufacturing products will produce wastewater. In food manufacturing-related industries, there are waste fluids produced when refining sugar and manufacturing beverages, as well as waste fluids from cleaning solutions. On the self-governing level and such, manufacturers independently establish safety standards for waste fluid. Harmful waste fluids and high concentration wastewater affects the ecosystem and its potentially detrimental effects on our bodies cannot be ignored. |

|

CASE STUDY Pre-treatment tank Wastewater Concentration Pre-Check Detect when an unexpected solution is mixed into wastewater. Aeration tank Wastewater Concentration Pre-Check Check ahead of time whether the concentration is appropriate for discharge to the aeration tank. If the concentration is too high, it will exceed the treatment capability. In such cases, wastewater is diluted by adding water. Effluent tank Prevent high concentration wastewater discharge Even in cases where the organic matter in wastewater is not completely decomposed, by monitoring and detecting the concentration of wastewater more than usual discharge of high-concentration wastewater can be prevented. |

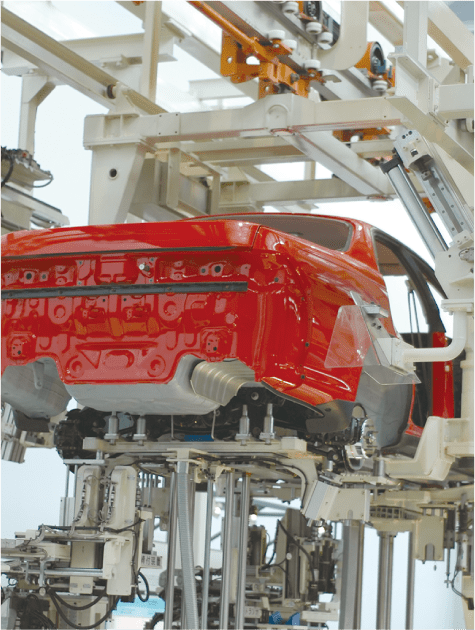

Surface Treatment Agents |

"Surface treatment" refers to a physical and chemical treatment applied to the surface of solid materials for aesthetic, ornamental, hardening, and enhanced corrosion resistance purposes. Types of treatments include cleaning, polishing, etching, and coating, but to demonstrate the maximum effectiveness of surface treatment, it must be performed with the same, standard concentration. Therefore, using in-line refractometers to check whether the concentration is, as usual, is immensely important. |

|

CASE STUDY Degreasing Concentration Control of Degreasing Solution It is important to monitor the concentration as it becomes contaminated over time. Rinsing Concentration Monitoring For Rinse Water Measures concentration of the rinse water used to wash chemical agents. Post-treatment coating (e.g. oil) Maintaining Proper Concentration The concentration of surfactant solutions lowers over time. No need to use other analyzers such as HPLC, etc. |

DMF・DMAC・DMSO |

DMF : Dimethylformamide DMAC: Dimethylacetamide DMSO: Dimethylsulfoxide These are widely used as solvents. Dimethylformamide (DMF) may be an unfamiliar name but it is very much used in acrylic fiber-forming and as a solvent for wet spinning. It is also used as a solvent for artificial leather and urethane-based synthetic leather. |

|

CASE STUDY Coagulation Tank DMF Concentration Check DMF is used as a solvent for polyurethane in the production of artificial leather. First, non-woven fabric is impregnated with a water-based aqueous solution containing a surfactant. Then, it is dipped in a DMF solution in a coagulation bath to undergo a urethane formation reaction. Since the DMF solution in the coagulation bath is gradually diluted with water from the previous step, the concentration control of the DMF aqueous solution is important because its quality affects the concentration. The DMF solution in the coagulation process is recycled through the recovery system, and in some cases, a refractometer is built into the recovery system. The method of producing artificial leather varies depending on the application, and a DMF solution may be used in the impregnation process. Case DMF is also used in the manufacturing process of rubber gloves. An in-line meter is installed in the wash tank concentration to ensure that DMF has been removed completely in the final wash process to monitor concentration. For an environmental and health standpoint as well, it is important to measure and monitor numerically whether the removal is complete. |

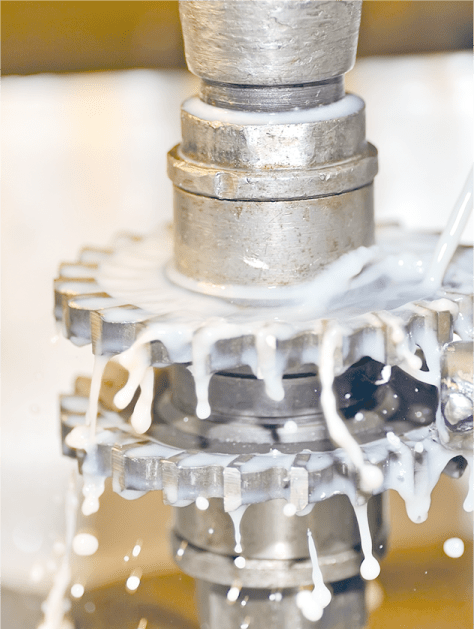

White Mold Release Agent |

In the process of making products such as cast-metal objects (casting), a chemical called a "release agent" is used to aid in smoothly and easily remove the product from the mold. There are many advantages in managing the concentration of release agents. If the concentration is low, product defects can occur, such as color stains on the product, or a section of the cast-metal object may chip off. If the concentration is high, de-molding can become difficult, requiring force to remove the product from the mold, which can warp the product. By managing the concentration of release agents, in conjunction with preventing defective products and errors, productivity can be improved. |

|

CASE STUDY Release agent application Maintaining Proper Concentration Measure the concentration of liquid agents to maintain consistent levels. Case At a site where a casting mold release agent is managed by an in-line meter, it is a semiautomated process, where an alarm lamp will light to notify the workers of any abnormalities. With the introduction of in-line meters, it is possible to check numerical values and receive alarms without requiring the workers to be onsite. It will contribute to improving and detecting lot of errors caused by mold not separating properly. Case At a location where it is installed as a sensor on a mold release agent mixing and delivery system, it is used for the concentration control of the collection and recovery of the mold release agent after use and the flow of metal before flowing into the mold. In the past, conductivity meters were used, but because of the high maintenance due to deposits accumulating on the electrode, refractometers are now installed. |

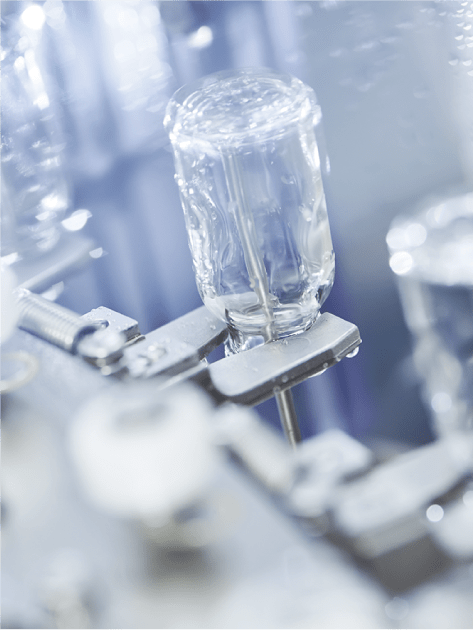

Hydrogen Peroxide

|

In modern Japan, many aseptically packaged products are used. A sterile filling and packaging system that makes it possible to preserve food such as milk, other dairy products, dessert, soft drinks, and highly viscous, liquid foods for a long time has been established. Many kinds of containers are used in this process; paper containers, glass, bottles, cans, plastic containers, PET bottles, and others. For example, in the bottling process of beverage production, a low concentration of hydrogen peroxide is sprayed inside a paper carton to sterilize it. At this point, it is necessary to use in-line refractometers to manage the optimal concentration for sterilization. |

|

CASE STUDY Flash pasteurization Concentration monitoring of Sterilization Solution In order to maintain consistency, the concentration of sterilization solution is measured. If the concentration is too high, it remains in the paper packaging, and if it is too low, the effect of sterilization will diminish. Beverage manufacturers are continually improving quality control measures to ensure that consumers receive safe products. Case One beverage manufacturer uses 35% hydrogen peroxide solution to clean paper packaging materials. In-line is installed to check the concentration change while using the same liquid for a week. Besides hydrogen peroxide solution, caustic soda may be used as a sterilizing solution. Case Another beverage manufacture-installed an in-line meter to measure caustic soda concentration (about 50%) used to wash beverage production lines. Here, the concentration the beverage itself can also be measured by an inline refractometer. |

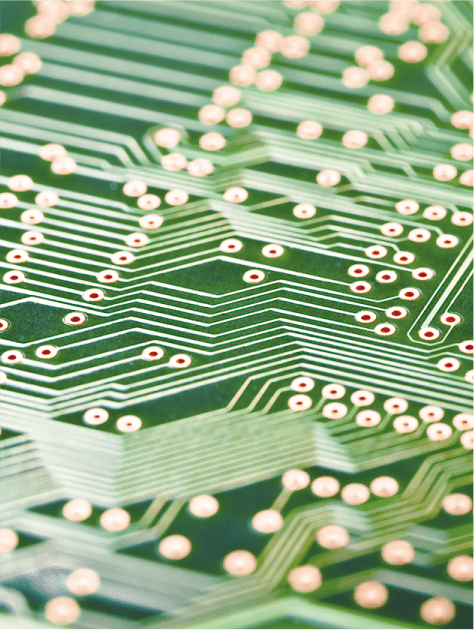

Resists |

Resists are rarely seen directly in our daily lives. Nonetheless, they are used in many familiar, common, places such as on top of electronic PCBs and semi-conductors which power electronic and electrical products, LCDs (liquid crystal), and printed materials. Resists are absolutely invaluable to items that are closely tied to our modern lives such PC and tablet monitors, and LCD TVs. This market continues to develop every day. |

|

CASE STUDY Resist coating Concentration Monitoring by Application Knowledge It is mainly applied for the purpose of the protective film and short circuit fault prevention. The green-colored films are known for protecting the substrate, but in fact, there are various types. The color used as resist variations and are not only for design purposes but also have practical applications such as hiding the wiring of the board and making the circuit design hidden. Knowledge It is also used for the purpose of improving image quality by highly controlling the cell gap of LCD as a photo spacer required for the liquid crystals. For example, when a resist is used as a spacer for advanced control, highly advanced = thickness is precisely controlled for graphical quality, thickness = concentration control by in-line meters. |

Plating Solutions

|

Plating is widely used in familiar, everyday items such as in smartphones and tablets, PCs, automobiles, and accessories. "Mekki" is the Japanese word for plating. Although the term may seem like it originated from a foreign loanword, mekki is actually Japanese in origin. Plating has an unexpectedly long history. Overseas, it has been used since the BC era, and in Japan, it has also been used since long ago, from the Kofun period. Plating has many expansive roles such as improving appearance, corrosion resistance, and abrasion resistance, and for function and performance. Just as plating serves many purposes, there are also many kinds of plating techniques. |

|

CASE STUDY Metal Plating Maintaining Proper Concentration The concentration of sulfuric acid used in the plating solution is controlled. Comparison With Other Principles Alternatively, using conductivity meters instead of in-line refractometers is an option. Some customers prefer refractometers for safety reasons and to avoid troublesome sensor replacement. |