Technical Articles

What is the F-gas Regulation?

The F-gas Regulation is an EU regulation to control systems containing specific greenhouse stimulating hydrofluorocarbons (HFCs). The new F-gas Regulation was published on June 9th, 2014 and has been effective since January 1st, 2015. The regulation governs that systems such as air conditioning and refrigeration units and fire extinguishing systems using certain gases must be logged and checked periodically for leakage. The new F-gas Regulation does not show filling volumes in kg but assesses the refrigerants according to their Global Warming Potential (GWP).

Come learn about different ways to manage cutting fluid concentration and pH to get the most out of your oil by watching a short walk-through at ATAGO factory!

In this video you’ll see how easy it is to use the:

- PAL-102S

- PAL-pH

- CM-BASEα

- PAN-1

- CM-BASEβ

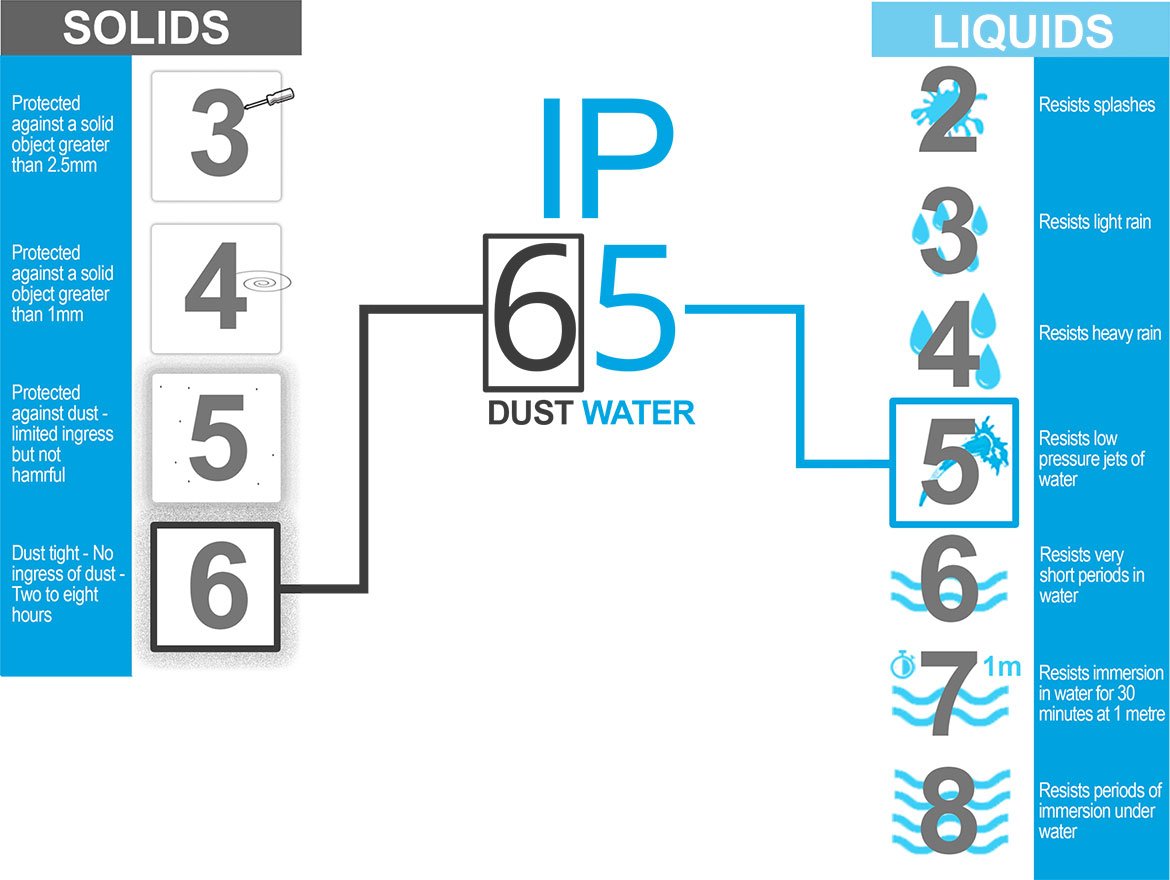

What is an IP rating?

IP (or "Ingress Protection") ratings are defined in international standard EN 60529 (British BS EN 60529:1992, European IEC 60509:1989). They are used to define levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (tools, dirt etc) and moisture.

What do the numbers in an IP Rating mean?

The numbers that follow IP each have a specific meaning. The first indicates the degree of protection (of people) from moving parts, as well as the protection of enclosed equipment from foreign bodies. The second defines the protection level that the enclosure enjoys from various forms of moisture (drips, sprays, submersion etc). The tables below should help make sense of it:

IP Ratings - what they mean.

IP Rated Enclosures - quick find chart

A number replaced by x indicates that the enclosure is not rated for that spec.

First Digit (intrusion protection)

- (or X - see section below): No special protection. Not rated (or no rating supplied) for protection against ingress of this type.

- Protection from a large part of the body such as a hand (but no protection from deliberate access); from solid objects greater than 50mm in diameter.

- Protection against fingers or other object not greater than 80mm in length and 12mm in diameter (accidental finger contact).

- Protection from entry by tools, wires etc, with a diameter of 2.5 mm or more.

- Protection against solid objects larger than 1mm (wires, nails, screws, larger insects and other potentially invasive small objects such as tools/small etc).

- Partial protection against dust that may harm equipment.

- Totally dust tight. Full protection against dust and other particulates, including a vacuum seal, tested against continuous airflow.

Second Digit (moisture protection)

- (or X - see section below): No protection.

- Protection against vertically falling droplets, such as condensation. ensuring that no damage or interrupted functioning of components will be incurred when an item is upright.

- Protection against water droplets deflected up to 15° from vertical

- Protected against spray up to 60° from vertical.

- Protected against water splashes from all directions. Tested for a minimum of 10 minutes with an oscillating spray (limited ingress permitted with no harmful effects).

- Protection against low-pressure jets (6.3 mm) of directed water from any angle (limited ingress permitted with no harmful effects).

- Protection against direct high pressure jets.

- Protection against full immersion for up to 30 minutes at depths between 15 cm and 1 metre (limited ingress permitted with no harmful effects).

- Protection against extended immersion under higher pressure (i.e. greater depths). Precise parameters of this test will be set and advertised by the manufacturer and may include additional factors such as temperature fluctuations and flow rates, depending on equipment type.

- (K): Protection against high-pressure, high-temperature jet sprays, wash-downs or steam-cleaning procedures - this rating is most often seen in specific road vehicle applications (standard ISO 20653:2013 Road Vehicles - Degrees of protection).

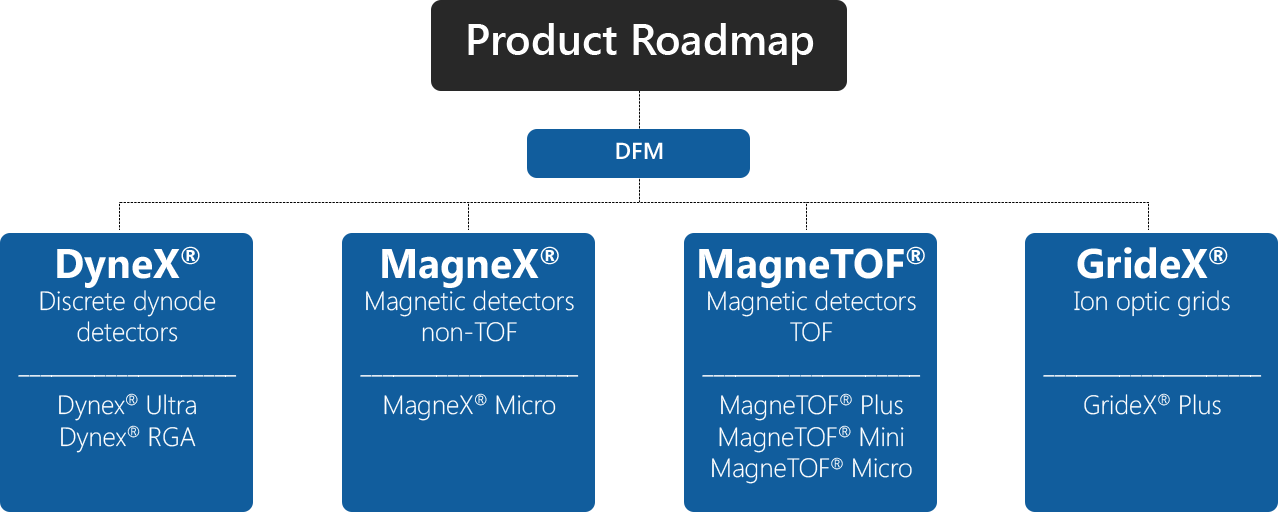

ETP Ion Detect major product range includes:

- OEM exclusive Quad, Ion Trap and Sector Electron Multipliers

- OEM exclusive TOF and MagneTOF Electron Multipliers

- OEM TOF ion/electron Optical Grids

- Restricted range of Instrument Specific End User Electron Multipliers

DyneX™

DyneX ETP’s next generation discrete dynode electron multipliers incorporate new dynode technology and electron optical concepts

- Improved operating lifetime

- Extended dynamic range

- High degree of customization available

MagneX®

MagneX magnetic detector technology takes the concepts deployed in ETP’s award winning MagneTOF technology into non-TOF applications

- Through miniaturisation bringing the power of magnetic detector technology to quadrupole and ion trap mass spectrometers

MagneTOF®

Next generation MagneTOF magnetic detector technology for TOF applications

- MagneTOF is rapidly replacing MCP’s as the technology of choice for TOF mass spectrometers

- Advantages include superior dynamic range, long lifetime and robustness – the MagneTOF is stable in air, eliminating the issues with MCP’s caused by moisture adsorption

GrideX®

Improve the efficiency of TOF-MS mass spectrometers with the parallel wire TOF-MS ion optical grid, pioneered by ETP. We use a revolutionary manufacturing method developed using stretched 18um tungsten wires to improve the ion transmission efficiency of TOF-MS mass spectrometers, leading to enhanced analytical performance.

- <20um flatness across a wide ion transmission area

- Greater than 92% ion transmission efficiency

Signal Processing

In today's TOF MS systems, the ion detection system is frequently floated to several thousand volts, and a fast transient signal has to be collected from this environment, back down to the ground for further processing. ETP's unique capacitive decoupling technology allows a <500ps pulse from one of our fast MagneTOF detectors to be processed with minimal impact on peak shape and line ringing. This optimises obtainable mass spectrometer resolution and mass accuracy even further.

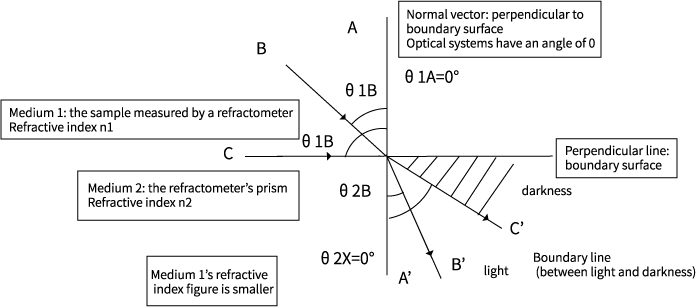

What are the principles of refractometers?

Snell's Law

Snell's law is a law that describes the passage of light through two nearby media. It is also known as the law of refraction.